DeconGel

Stronger. Smarter. Cleaner.

A breakthrough hydrogel enabling unparalleled decontamination performance

- ✓ Green technology: non-hazardous, pH neutral

- ✓ Nuclear, chemical, biological remediation

- ✓ Cost-effective (10X)

- ✓ Unparalleled performance

- ✓ Over $11M of R&D invested

DeconGel™ is a water soluble, biodegradable decontaminant that has demonstrated unparalleled performance in removing chemical, biological and radiological contaminants and reducing labor, waste and disposal costs.

DeconGel™ is OSHA non-hazardous, RCRA certified and approved for WIPP disposal. DeconGel has been tested by numerous agencies and enterprises, such as the U.S. Navy, Department of Energy, Department of Homeland Security, U.S. Army-Joint Program Office for Chemical, Biological, Radiological and Nuclear and Explosives, and the Japan Ministry of Environment.

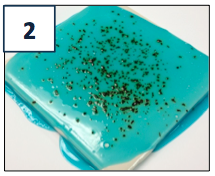

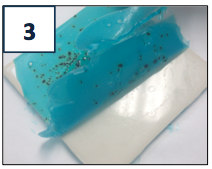

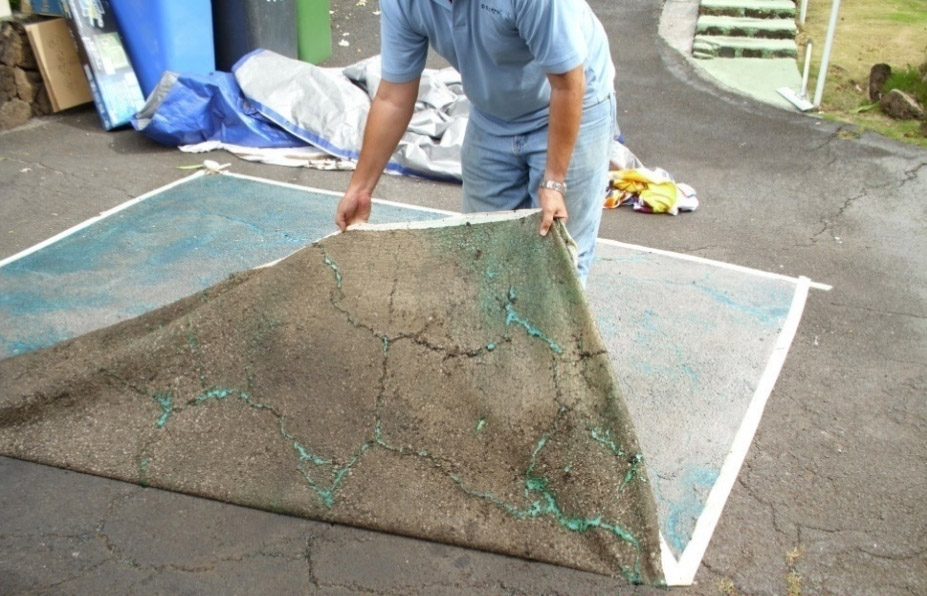

Apply. Dry. Peel.

- Nano-molecular penetration

- Chemically binds and encapsulates surface contaminants

- Mechanically lifts particulates

- Dries into easy-to-peel film

- Works on many complex surfaces

- Brush and spray formulations

Next-generation decontamination technology

- Works on LIQUID and SOLID particulates

- ZERO preparation

- Penetrates and removes contamination from cracks, pores, and voids at the nano-molecular level

- Works on variety of surfaces (smooth, rough and painted) and complex geometries

- Minimal odor, respirators not required during application or peeling unless mandated or when used in close quarters

- Dries into a high tensile film that is easy to peel (non‐sticky) and discard

DeconGel is formulated for the removal of many solid-state contaminants & some liquids

- Am-241

- Pu-238

- Pu-239

- Pu-240

- Pu-241

- Pu-242

- Cs-137

- Cs-134

- Co-60

- Mn-54

- Fe-55

- Ni-63

- Ni-59

- Sr-90

- Co-58

- Mercury

- Lead

- Cobalt

- Arsenic

- Chromium

- Beryllium

- Thallium

- Zinc

- Nickel

- PCBs

- Asbestos

- Oil

- Mold

- Mildew

- Soot/fine particulates

Restoration of cast stone fireplace (fine soot)

Before

Before After

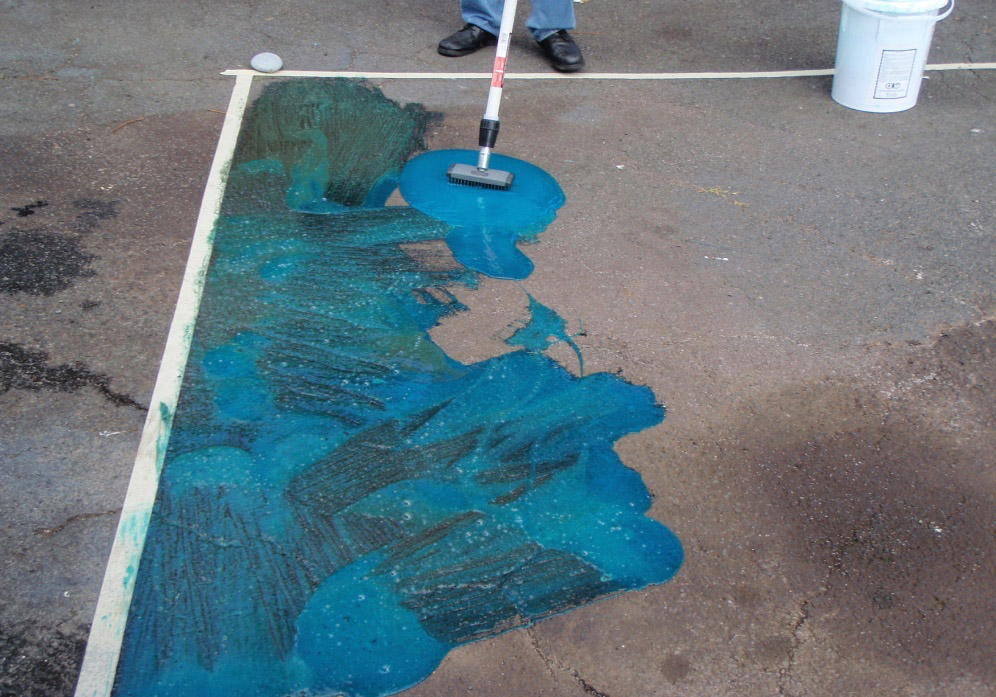

AfterOil Contamination on Driveway

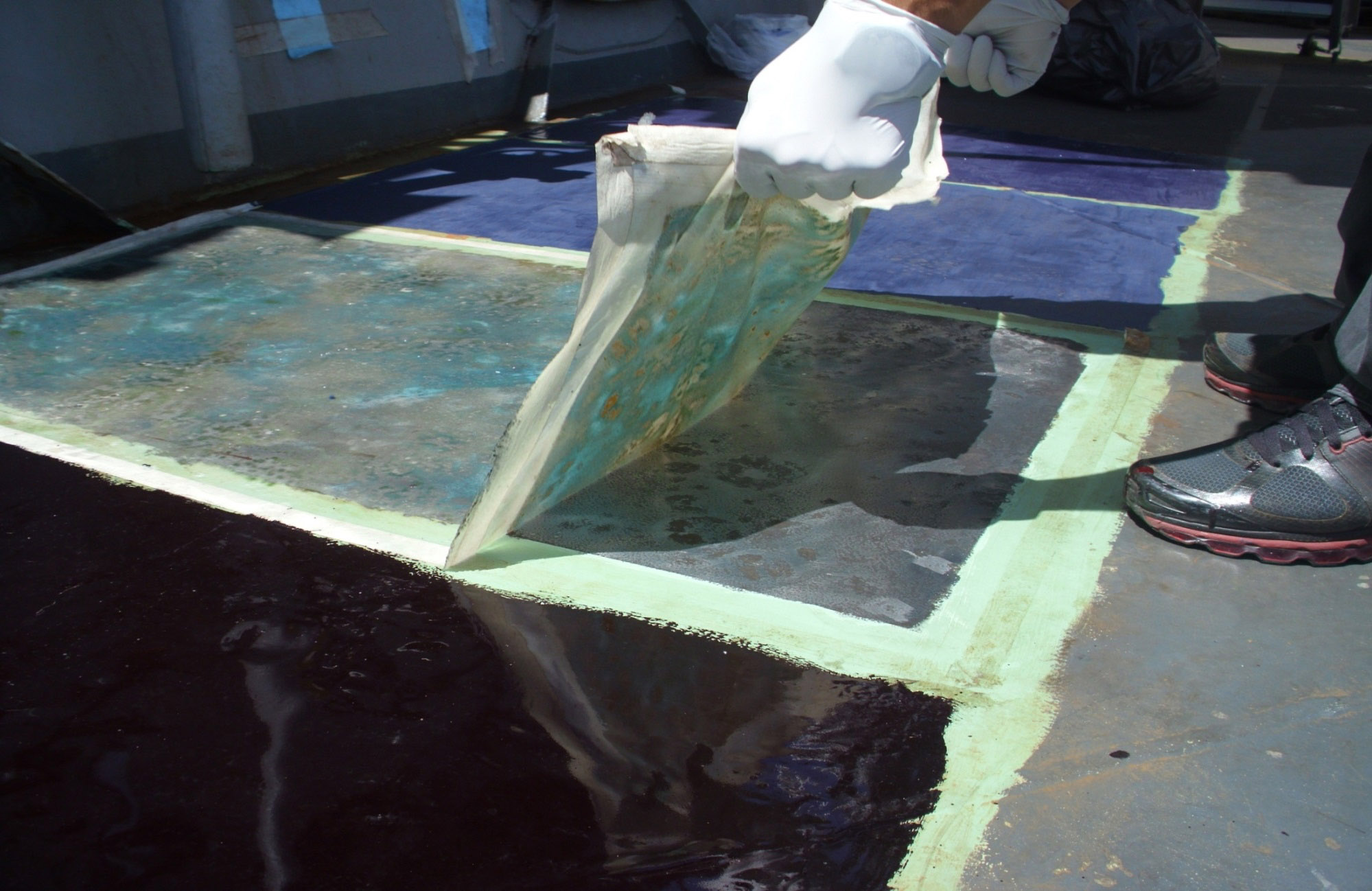

Apply and let dry

Then peel…encapsulates ALL contaminants

Disposal: minimizes waste –

45 lbs. wet; 7.5 lbs. dry (20 Liters)

- Lower waste equals cost savings

- Lower waste equals reduced manpower

- Lower waste equals reduced logistics

- Lower waste equals faster turnarounds

Waste remediation by-product comparison:

100,000 sq. ft. of nuclear contamination

Waste Generated Using DeconGel

13,000 lbs. = $104k

Used on Chemical compounds and hazardous materials

- Aldehydes (Glutaraldehyde)

- Alkaloids (Nicotine)

- Aromatic Liquids (Toluene)

- Aromatic Solids (Naphthalene)

- Arsenic Compounds (Arsenic Trioxide (As2O3)

- Elemental Aluminum Powder (Al)

- Aluminum Oxide (Al2O3)

- Aluminum Chloride (AlCl3)

- Aluminum Potassium Sulfate (AlK(SO4)2))

- Antimony

- Barium Compounds (Barium Chloride (BaCl2)

- Barium Carbonate (BaCO3)

- Beryllium Compounds

- Beryllium Surrogates (Elemental)

- Cadmium Compounds (Cadmium Chloride (CdCl2)

- Cadmium Oxide (CdO)

- Chromium Compound (Potassium Chromate (K2CrO4)

- Cobalt

- Copper Compounds (Copper (elemental), Copper (I) Oxide)

- Crude Oil

- Cyanide Compounds (Potassium Ferricyanide (K3[Fe(CN)6])

- Halogenated Solvents (Tetrachloroethylene)

- Industrial Coolants (Ethylene Glycol)

- Industrial Solvents (m-Cresol)

- Iodine Compounds (Potassium Iodide (KI)

- Iron Compounds (Iron (II) Chloride (FeCl2)

- Lead Compounds (Lead (II) Oxide (PbO)

- Lead (II) Sulfate (PbSO4)

- Mercury Compounds (Mercury (II) Chloride (HgCl2)

- Mercury Oxide (HgO) and Mercury elemental

- Navy Dye Marker

- Nickel Compounds (Nickel Nitrate (Ni(NO3)2)

- Organic Acids (Benzoic Acid)

- Organic Bases (Triethylamine)

- Tin compounds (Tributyltin Chloride)

- Methamphetamines

- Molybdenum

- Nickel

- PCB

- Pesticides (DDT)

- Plastics Feedstock (Aniline)

- Phenolic Compounds (Catechol)

- Selenium

- Silver

- Vanadium

- Zinc

What makes DeconGel so Effective?

- Surfactants – aggressive surfactants, emulsifies hydrophobic materials, stabilizes metals

- Chelates – solubilizes heavy metals

- Thixotropes – allows product viscosity to break down under shear simultaneously allowing thick wet films on vertical surfaces and spraying

- Wetting Agents – wets out surfaces, particulates and the interior of porosity

- Defoamers – increases film toughness, decreases adhesion, re-coat capable (can accept multiple coats)

- Dye – allows visualization of wet film thickness and location (e.g. complete coverage)

- Biocide – stabilizes product during storage

- Buffer – near neutral pH

Focused product suite developed for targeted applications

General Design information: DeconGel 1108/1128

- Appearance:Viscous polymer gel

- Shelf Life:5 years, re-certifiable

- Density:8.5 lbs. per gallon

- Percent Solids:15%

- Dry Film Thickness (DFT):20% of Wet Film Thickness (WFT)

- Volatile Organic Content:Zero

- Thinner/Solvent:Ionized Water

- Temperature Use Range:40F to 120F

- Decontamination Factor:up to 100%

- OSHA Status:OSHA Non-hazardous under (29 CFR Part 1910.1200)

-

Flammability:Non-flammable, but incinerable

Liquid class III B, under OSHA (29 CFR 1910.1200);

flashpoint >200°F - Melting/Freezing point:0°F

- Boiling point:212°F

- pH:5.0 – 7.0

Proven effective in independent government and customer tests

- Environmental Protection Agency – effective against radioactive isotopes

- Department of Energy – effective against radioactive isotopes

- DOE – Environmental, Security, Safety and Health Achievement Award/approval for beryllium decontamination

- U.S. Navy – Approved for use at Puget Sound Naval Shipyard; also for liquid petroleum contamination in shipboard tanks

- Naval Air Systems Command – safe for use on a range of materials

- Japan – approved for use at Fukushima Daiichi nuclear power plant and surrounding communities

- Resource Conservation and Recovery Act (RCRA) – certified as non-hazardous

- WIPP-certified

- Approved for use in GE reactors

Key advantages of breakthrough technology

- User-friendly application reduces total decontamination time, labor cost, and waste volumes by up to 80%

- Labor-intensive pressure washing often ineffective, entails high labor hours and significant waste disposal costs

Broad range of government and industry customers

- National Institute of Standards and Technology

- Defense R&D Canada

- Idaho National Lab

- VA Medical Center

- Lawrence Livermore

- Oak Ridge

- Perry Nuclear

- Savannah River

- Fermi Nuclear

- Hatch Nuclear

- Pearl Harbor Naval Shipyard

- Naval Research Lab

- Naval Corrosion Lab

- Edgewood Chem-Bio Center

- Dept. of Homeland Security

- Bureau of Reclamation

- BAE Systems

- TRW Inc.

- Conoco Phillips

- Thermo Fisher Scientific

- Battelle Memorial Institute

- Geisinger Health System

- First Energy

- HTDV Hawaii

- ALCOA

- Levitt-Safety

- Shaw Environmental

- Triumvirate Environmental

- National Geographic

- Safety and Ecology Corp

- VWR Inc.

- Fastenal Inc.

- Matson Shipping

- VWR International GmbH, GE

- Atomic Energy CN

- Ontario Power Generation, CN

- Berthold Technologies, EU

- E.ON Group, GE

- Unitech Services Europe, EU

- Biological Health Services, UK

- Southern Scientific, UK

- Dept. of National Defense, CN

- Royal Military College, CN

- National Research Council, CN

- Overplus Global Services, SA

- Nigerian LNG Ltd

- EnviroKorea Co., Ltd.

- Tokyo Electric Power Company

- Japan Aerospace Corporation

- Zen Ei Corporation, JP

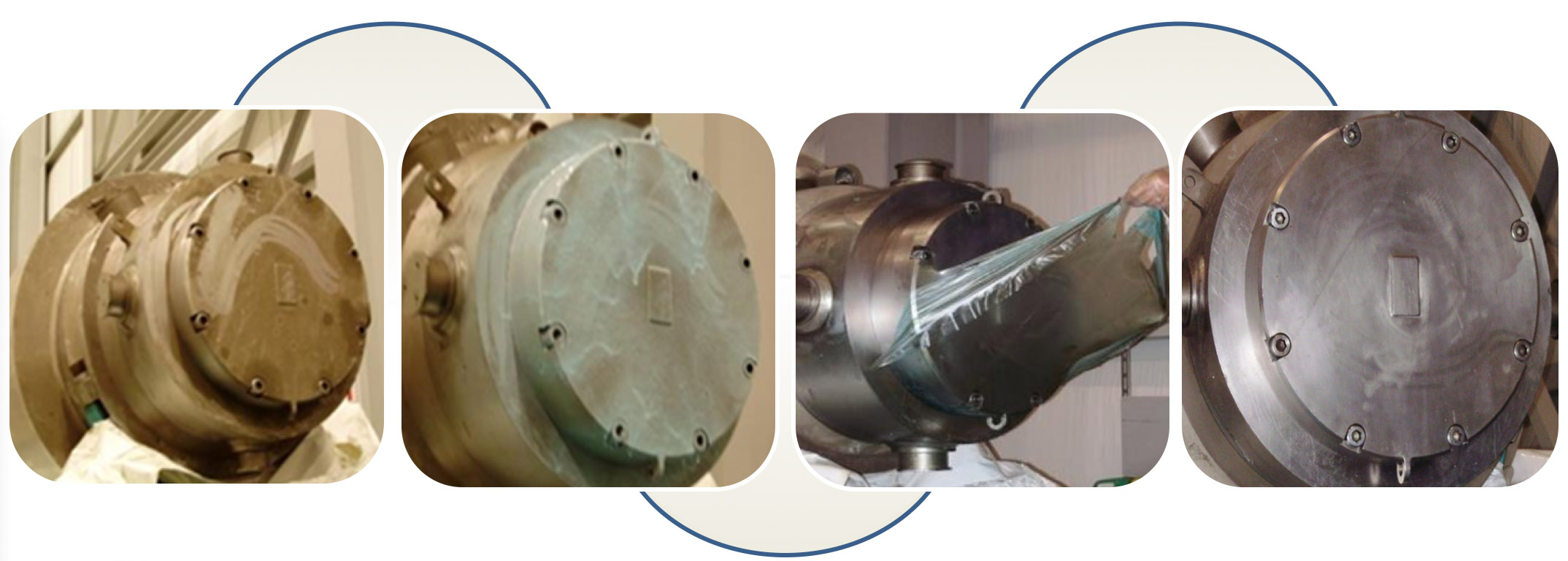

Cask end cap – decontaminates complex surfaces without abrasion or damage

U.S. Department of Energy National Lab customers

Oak Ridge National Lab

Oak Ridge, TN

- Savannah River

- Los Alamos

- Pacific Northwest

- Sandia

- Lawrence Livermore

- National Energy Technology

- Oak Ridge

Commercial nuclear power plant customers

- Perry Nuclear Power Plant

- Bruce Nuclear Generating Station

- Nine Mile Point Nuclear Station

- Braidwood Generating Station

- Ontario Power Generation

- Peach Bottom Atomic Power Station

- San Onofre Nuclear Generating Station

Bruce Nuclear Generating Station

Ontario, CA

Live chemical warfare agent (CWA) decontamination

- Joint Program Executive Office for Chemical, Biological Defense (JPEO-CBD) and Dugway proving grounds performed classified field tests of DeconGel on emerging CWA threats

- JPEO-CBD and Dugway reports that DeconGel to be an exceptional physical decontamination method (data classified)

- In-house tests on VX and sulfur mustard simulants showed decontamination to levels below limit of detection across a variety of surfaces

- DHS R&D contract currently exploring a highly effective bio-kill implementation of DeconGel

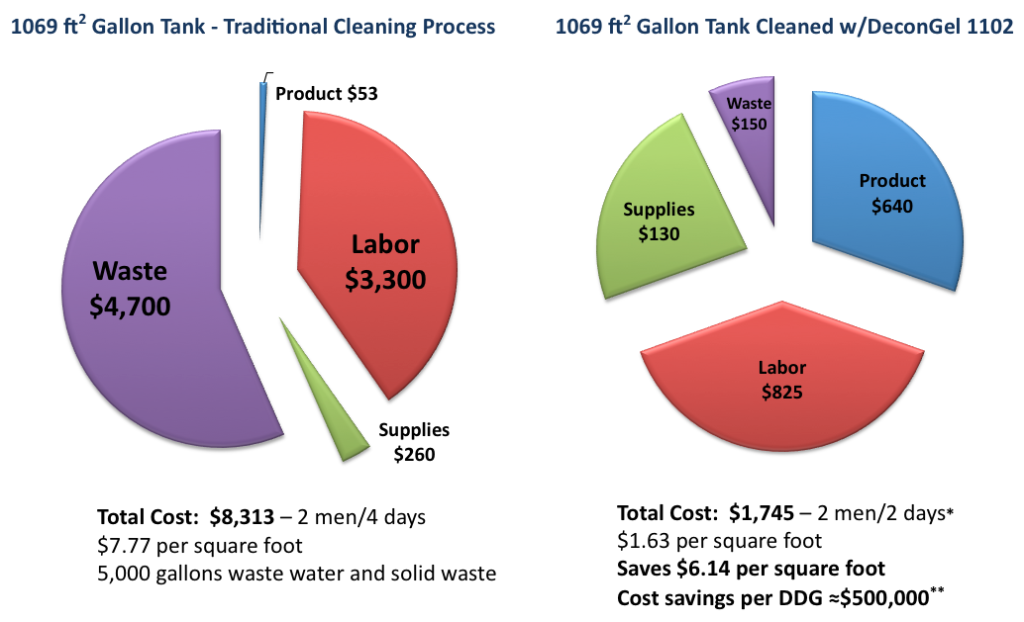

Remediation of bilge sludge and petroleum fuel deposits

DeconGel cost benefit analysis – Navy DDG

*Data from U.S. Navy

Remediation of PCB contamination aboard USS Missouri – 60% cost savings

| Application | Stainless Steel | Aluminum | Concrete* |

|---|---|---|---|

| DeconGel 1102 (Non-Brushed) | >94% | >94% | >87% |

| DeconGel 1102 (Brushed) | 100% | 100% | 100% |

Cost analysis: decontamination of PCB-contaminated spaces aboard USS Missouri

- Product and equipment cost: solvents, clay and PPE ($732.50)

- Time required: 35.5 man-hours over 3 days ($2,433)

- Transportation and disposal of waste generated: 2,127 gallons @ $0.55 per gallon ($1,170)

- Total decon costs: $4,335 and 3 days

- Product and equipment cost: 5.28 gallons at $121 per gallon and PPE ($773)

- Time required: 10 man-hours over 2 days ($685)

- Transportation and disposal of waste generated: 2 barrels at $150 per barrel ($300)

- Total decon costs: $1,758 and 2 days

- 60% LOWER total costs using DeconGel and 33% FASTER turnaround time

Decontamination of metal contaminants at electronic recycling facility

| Contaminant* | Swipe Before DeconGel | Swipe After DeconGel® “Troweled” | Decontamination Efficacy (%) | Swipe After DeconGel® “Scrubbed” | Decontamination Efficacy (%) |

|---|---|---|---|---|---|

| Antimony (Sb) | 386 | 74.8 | 81% | 74.5 | 81% |

| Barium (Ba) | 3630 | 223 | 94% | 65.7 | 98% |

| Cadmium (Cd) | 113 | 5.1 | 96% | 1.7 | 99% |

| Chromium (Cr) | 276 | 14 | 95% | 9.9 | 96% |

| Cobalt (Co) | 85.6 | 6 | 93% | 2.9 | 97% |

| Copper (Cu) | 3600 | 149 | 96% | 50.1 | 99% |

| Lead (Pb) | 5890 | 339 | 94% | 106 | 98% |

| Molybdenum (Mo) | 55.8 | 2.9 | 95% | 1.6 | 97% |

| Nickel (Ni) | 1970 | 93.8 | 95% | 29.9 | 98% |

| Selenium (Se) | 2.1 | ND | 100% | ND | 100% |

| Silver (Ag) | 338 | 26.5 | 92% | 19.9 | 94% |

| Vanadium (V) | 21.8 | 1.7 | 92% | 1.1 | 95% |

| Zinc (Zn) | 10300 | 909 | 91% | 237 | 98% |

| Mercury (Hg) | 7.3 | 2.6 | 64% | 0.79 | 89% |

Lead dust remediation at Pearl Harbor Naval Shipyard – Building 6

- 52,000 sq. ft. foundry complex vacated due to lead dust contamination

- Initial DoD decontamination efforts determined to be not cost justified

- EPA DeconGel field test demonstrated excellent efficacy and cost savings:

- Over 95% decontamination to below OSHA acceptable limits

- Demonstrated cost savings of over 36%

- GEL now working with NAVFAC for remediation of entire complex

Cleanup of hydraulic/jet fuel fluid spills on USS O’Kane flight deck

Problem: recurring deck rust and corrosion

- CBIP asked to demonstrate utility of DeconGel as surface preparation tool

- Object of test was recurring corrosion and rust on DDG

- 8 panel areas were selected

- All surfaces prepared with grinding, then DeconGel 1102 as the “wiping process” to remove chlorides and metal particles and other contaminants

DeconGel used to clean panels prior to primer application

Summary

- DeconGel is a proven and tested product and represents the latest technology for decontamination of hazardous and radioactive materials

- Hazmat applications are infinite, but require client knowledge of operational processes and environmental safety and health regulations

- Proposed changes to U.S. Navy regulations for use in bilge tank cleaning and other ship cleaning applications in process; products approved for us at Puget Sound Naval Shipyard

- Can provide competitive edge with highly effective, differentiated products that can save 40+% in total project cost

- Application training for major clients; comprehensive product briefings available upon request

Galen Enterprise LLC

- Contact Details:

- Galen I. Ho, President & Owner

- – Cell: 808-753-9400

- – email: galenenterprise@aol.com

- – Cummings Center, Suite 365E

- – Beverly, MA 01915

- Galen I. Ho, President & Owner

- Call us for pricing, order processing, and additional technical information

- Detailed, in-person product briefings also available upon request